Results from the i+SCabin2.0 research project are expected to become available by mid-2023. (Photo courtesy of Boeing Global Services)

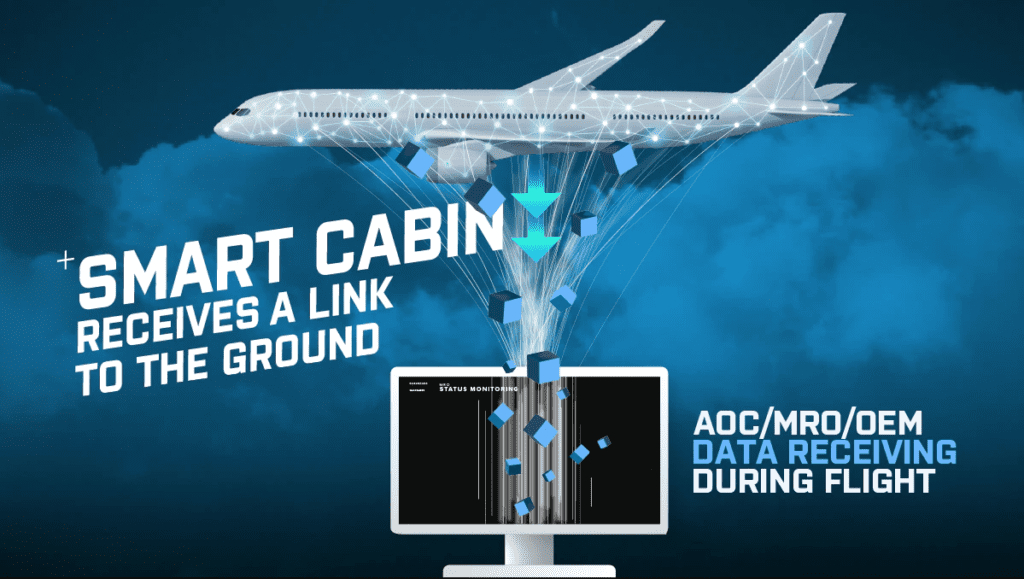

Boeing is moving forward with the second phase of a research project designed to provide networked aircraft cabin components with the ability to send data and information to ground-based airline, maintenance, and OEM information systems with “i+SCabin2.0.”

According to a July 8 announcement from Boeing Global Services (BGS), i+SCabin2.0 is a follow-on initiative to a research project first launched as part of Boeing’s 2019 ecoDemonstrator program that demonstrated the use of smart cabin sensors to capture the technical status or health of a commercial aircraft cabin filled with passengers in real time. The 2.0 phase of the project seeks to add a data link between the networked cabin components and relevant ground systems.

“The approach of the new i+SCabin2.0 research project is to enable sharing of data obtained from the cabin with ground stations during the flight for automated processing and evaluation using artificial intelligence,” according to the BGS announcement.

Jeppesen has been tasked with using the smart sensors and edge computing technologies introduced during the first phase of the research initiative to create an operational digital twin of the average Boeing aircraft cabin that could improve the maintenance and records management processes for airlines and aircraft lessors. Further, Jeppesen seeks to capture and analyze data about individual cabin components and systems for maintenance data analytics purposes.

One of the key goals in this second phase of the smart cabin research project is the development of a generic standardized “software application hosting environment designed to accommodate applications from manufacturers, OEMs, and service providers running on an onboard cabin server.”

Boeing is working with a European alliance of aerospace industry suppliers for the i+SCabin2.0 project that includes Airbus Operations GmbH and is led by Diehl Aerospace, the Überlingen, Germany-based interiors and avionics supplier. An update on their involvement in the project released by Diehl last month notes that the company has some specific research goals it would like to achieve as part of the project as well.

“Another work package investigates wireless mechanisms that assign specific devices to a functional position,” the company writes. “For example, a passenger service unit can be assigned to a specific seating group. As part of i+SCabin2.0, Diehl investigates whether and how the determined position information can contribute to digitizing the cabin configuration process.”

Diehl will also use their involvement in the project to assess the possibility of automating cabin inspections and accelerating the passenger onboarding process, among others. The company expects the i+sCabin2.0 research project’s results to become available by the “middle of 2023” presented in a technology demonstrator.