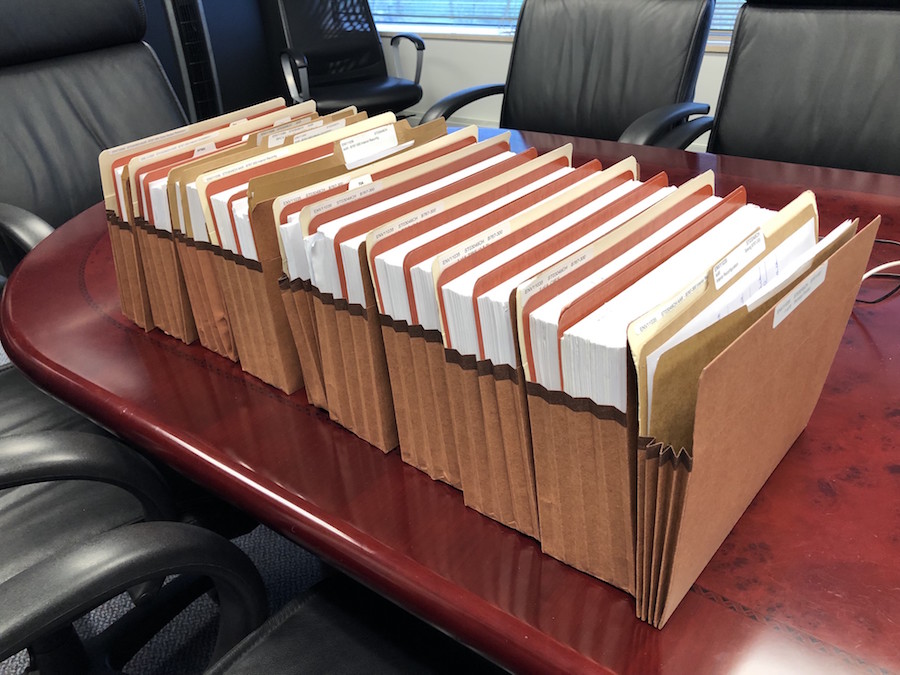

The folders of documents pictured here represents the amount of paper work required to document a Boeing 767-300 interior reconfiguration. The newly formed Independent Aircraft Modifers Alliance is looking to standardize the way MROs document the aftermarket upgrade process. Photo: Envoy Aerospace

Some of the world’s largest providers of aftermarket aircraft maintenance, repair and overhaul are working together to develop new standards to help change the way airlines and leasing companies perceive documentation and quality of Supplemental Type Certificates (STCs).

EAD Aerospace, Envoy Aerospace, Etihad Engineering and Lufthansa Technik have collectively formed the Independent Aircraft Modifier Alliance (IAMA) with this goal in mind.

Nicole Noack, head of IAMA, who also leads the strategic partnerships division of Lufthansa Technik, said the group wants to change the way the processes provided by aftermarket MRO companies versus original equipment manufacturers (OEMs).

“Naturally, our customers feel the OEM solution is more standardized as compared to the STC development process; specifically, the usability and access of documentation or the after sales process,” she said.

“The independent STC providers – world wide – vary in those concerns. STC providers often offer faster and more flexible solutions (e.g. turn-key solutions) for mixed fleets, but the variable fulfillment processes are more and more seen as a risk,” Noack added.

While the STC process and its associated airworthiness requirements are standard, the way aftermarket organizations document their ability to achieve regulatory airworthiness standards can greatly vary from one part of the world to another. The alliance has been formed to standardize the type of quality aircraft operators and leasing companies can expect when seeking modifications from independent providers.

A technician checks for leaks at Lufthansa Technik’s modification facility. Photo: Lufthansa Technik.

Noack describes aftermarket modifications occurring under OEMs and MROs as similarly requiring massive amounts of paperwork for certification data. There are also design documents provided in the form of wiring diagrams, installation drawings, instructions and material lists. The documentation provides each MRO a way of understanding each individual aircraft modification down to every pin and screw required to enable it, Noack said.

Operators also receive instructions for continued airworthiness, and supplements to flight and maintenance manuals to provide guidance about the modification over the life cycle of the aircraft. The way MRO providers document this design data can greatly differ, which is why IAMA is looking to standardize the process.

“The complexity within the process for an integrator, such as the STC providers, lays not necessarily in the regulations and paperwork, but in the management of all interfaces of stakeholders in a modification: the operator, the manufacturers who supply components such as seats, galleys or the necessary equipment for installation like cable harnesses and structural integration kits. With certain standards to be set, we see a lot of potential to reduce complexity for those stakeholders too,” said Noack.

Building more predictability into the aftermarket modification process is another major goal for IAMA. Noack says this has become more important as the fleet of leased aircraft continues to grow. In comparison to airlines, leasing companies are increasingly concerned about the transferability of modified aircraft between regions, especially as civil aviation regulators continue to adopt and enact new mandates such as those requiring ADS-B coming up in 2020 or new aircraft tracking requirements taking effect in 2021.

Among the trends Lufthansa Technik is seeing right now in terms of demand for aftermarket modifications, Noack said the biggest common theme is the customization of aircraft cabins with new in-flight entertainment and connectivity systems. Operators are also continuing to seek ADS-B compliance and upgrade their aircraft to enable predictive aircraft maintenance.

Founding and future IAMA members will use the alliance as a forum to discuss ongoing concerns they’re hearing from customers regarding documentation, data availability and dealing with different civil aviation regulatory agencies. It will become an ecosystem for aftermarket aircraft modifiers to shape the way operators perceive quality associated with their STCs in the future.

That process will begin by developing a new IAMA rulebook that includes feedback and comments about how the aftermarket STC quality documentation process can be improved, prior to introducing a new official standard. Noack said IAMA is also inviting airlines and leasing companies to become members so that their input can be reflected in the development of their new standard.

“Ultimately we want to position the IAMA labelled STC as a brand for predictable quality. To be part of IAMA in the early stage gives all kinds of organizations the opportunity and voice to shape the standard, set priorities and to ensure the stakeholders perspective is met. With the IAMA brand STC, the end-customer gets more certainty and therewith choice for future modifications,” said Noack.