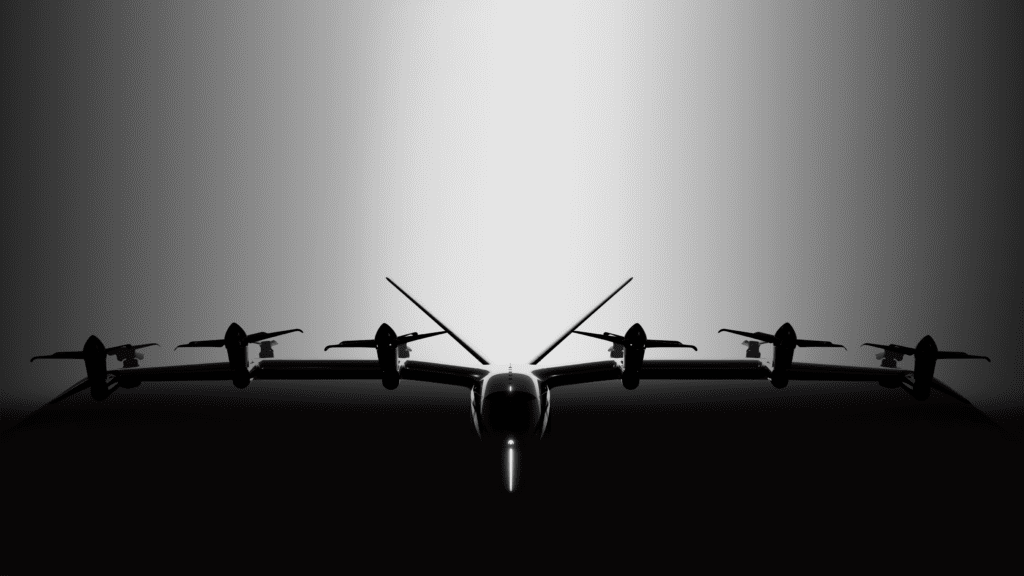

Archer recently revealed the silhouette of its eVTOL aircraft, Midnight. We spoke with two members of the design team at Archer to learn more about their approach to designing the aircraft and its unique components. (Photo: Archer)

Archer Aviation recently revealed the name of its electric vertical take-off and landing (eVTOL) aircraft, Midnight. While a detailed rendering of the aircraft has not yet been released, Archer shared a photo depicting the silhouette of its eVTOL. The company has completed the Preliminary Design Review and is targeting 2024 for achieving certification of Midnight.

Two members of Archer’s design team spoke with Avionics International this week about designing the interior and exterior of the aircraft. Juliette Allegra, CMF (Color, Materials, Finish) Designer at Archer, joined the company a year ago and comes from a background in the aerospace and automotive industries. Erik Saetre is a Vehicle Designer with an educational background in engineering and has been with Archer for about two years. He worked in the marine industry in Norway designing a search-and-rescue patrol boat before getting into transportation and automotive design. He has worked for Land Rover and Porsche as well as General Motors.

Erik Saetre, Vehicle Designer, and Juliette Allegra, CMF (Color, Materials, Finish) Designer (Photo: Archer)

Check out our question-and-answer session with Allegra and Saetre about the design process at Archer, the eVTOL’s unique features, and the most important design considerations for the aircraft.

Avionics: What brought you to Archer?

Juliette Allegra: The eVTOL industry is pretty new, but it is about to really change the way people are commuting. We will be able to explore the world like never before, which is pretty amazing. We are also here to save people time in day-to-day life.

Erik Saetre: The main reason I wanted to join Archer was the leadership team. Julien Montousse—and his credentials—was a big draw. I think automotive and transportation on the 2D grid is so “known.” I liked being able to join this new frontier and industry and revolutionize transportation as we know it, taking it into 3D.

What are you working on these days?

Juliette Allegra: Every day is different. I am in charge of the development and application of the Archer CMF strategy for conceptual and production aircraft as well as vertiports and infrastructure. I create digital concepts and renderings, also physical concepts with material samples, panels, and things like that.

I collaborate every day with interior and exterior design, and I work a lot with Erik on material development—specifically the geometry and architecture. I also collaborate with engineering, branding, manufacturing, purchasing, and suppliers to execute design intents. I also source and develop materials to maintain the innovation within our CMF library.

Erik Saetre: I am responsible for executing and designing the exterior of the aircraft along with our other exterior design specialist, Young-Joon Suh. We do manual digital sketching, 3D modeling, rendering, animation. We work with the engineering team and do constant iteration.

There has been a huge emphasis on the design of the seats. We’ve gone through numerous physical and digital iterations, testing to get the most ergonomic, perfect fit. It’s the most comfortable and lightweight seat; it’s really amazing.

Above is Archer’s Maker eVTOL aircraft. (Photo: Archer)

What are some of the most unique design aspects of Archer’s aircraft?

Erik Saetre: Our approach to the exterior design and the architecture itself sets the tone for the cabin and everything else. The architecture is designed and centered around the human being. Positioning of the wing, height, clearances, everything aims to make getting in and out of the vehicle as effortless as possible, and also being comfortable within the cabin.

The team really worked on sculpting the surfaces of the aircraft to reflect the environment around it. In that way, you’re kind of bringing life and emotion into the product. A good example of that in the automotive world is a rear fender on a Porsche—the surfaces are so taut but so sculpted, and it’s reflective; it has so much light. That’s what we’re trying to achieve.

Juliette Allegra: The idea with CMF is not to apply materials, or paint, or colors, it’s really trying to find symbiosis between materials and geometry. We have different requirements than the automotive industry. It’s very different, and it’s very challenging.

Saetre: We put a lot of emphasis on making the aircraft look equally as good in the air as on the ground. A lot of effort and innovation has gone into executing the landing gear, and giving it a solid, stable, and safe-looking stance. It has a very confident look and we think that’s very unlike any other aircraft at the moment.

Allegra: We are really creating a platform here. The idea is to emphasize the customer experience. We are trying to get away from what’s popular in the aviation industry right now. With CMF, we are trying to develop a premium product that will allow people to commute faster, and therefore give them the opportunity to explore and connect with their environment. Everything is studied: geometry shapes, architecture, and CMF, we are really pushing for a great experience for the consumer. We are building around them, actually.

What are some of the obstacles or challenges that the design team faces?

Juliette Allegra: We do face several requirements that are different from the automotive industry. The main one is the weight. It’s basically the main requirement for a CMF designer. There is absolutely no room for ornament or opulence.

Another requirement is taking a sustainable approach. This is very important to us. We are working with suppliers and engineers to implement new materials within the aerospace industry that are lightweight, sustainable, and very durable.

Erik Saetre: Weight restrictions and requirements have also been a massive enabler, I think. We’ve managed to create a very lean and athletic volume of fuselage; it’s become very efficient and very aerodynamic. It’s been a challenge, but it has enabled good design and good function.

Another big focus for us, with regards to the cabin, is the open visibility to the landscape and environment, and this kind of integration. I think that’s something unique that the cabin will offer. It’s such a different point of view—much lower to the ground than you would be in a commercial airliner.

We released the silhouette of Midnight; I think that image speaks to how we’re conveying upward motion. The very premise of the VTOL is the verticality of it. You see the silhouette and outline of the wing—it has this kind of upward pull motion to it.