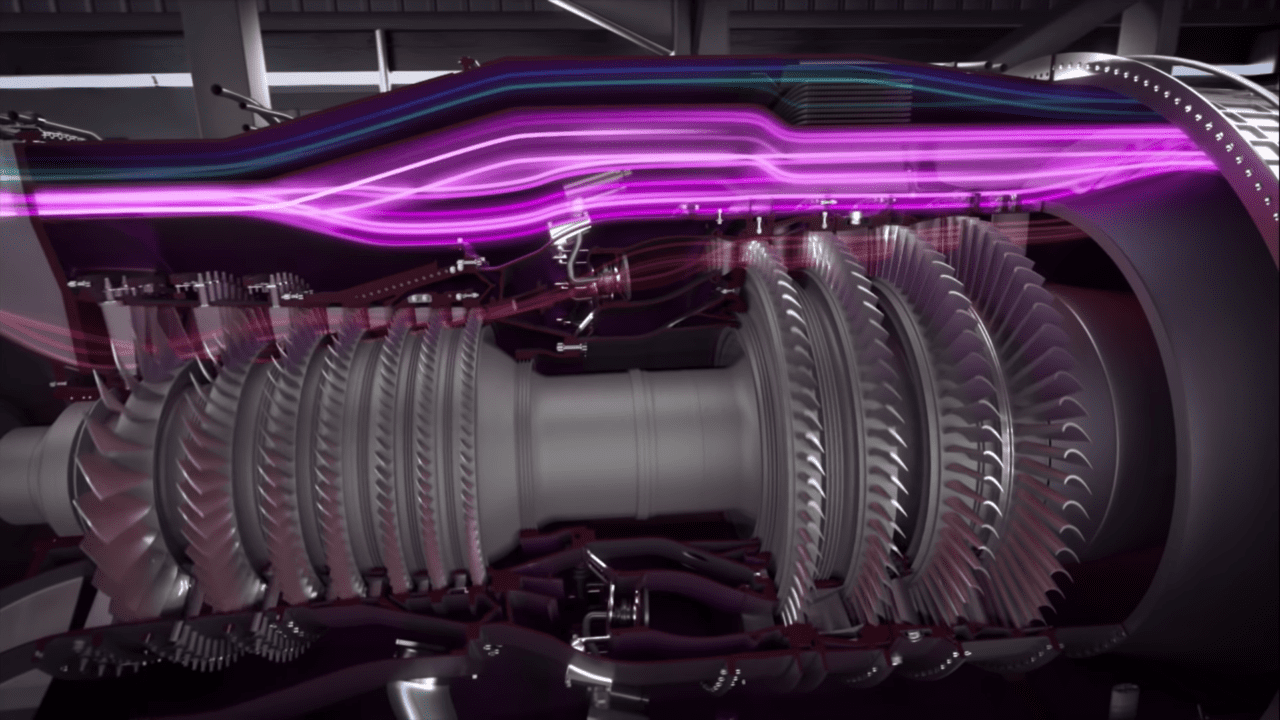

GE promotional materials showing the three air streams in the XA100 engine. (GE/AVI screenshot)

GE Aviation has completed the detailed design process of its XA100 engine under the U.S. Air Force’s Adaptive Engine Transition Program (AETP), the company announced Thursday.

The latest development means that GE can send engineering drawings out to its supply chain to get engine parts manufactured, according to David Tweedie, general manager for advanced combat engines at GE.

In accordance with AETP requirements, the XA100 ramps up engine thrust by 10 percent while simultaneously improving fuel efficiency by 25 percent over what would typically be possible with a fighter jet engine. The key is XA100’s variable cycle that allows for adjustment to the bypass ratio and fan pressure.

“Historically, the big turbofans have a much lower bypass ratio and a much higher fan pressure ratio, and that gives you very high specific thrust,” Tweedie said. “For a given technology, you can either optimize for fuel efficiency or thrust depending on what you want the aircraft to do.”

Traditionally, he said, militaries have lived with low fuel efficiency in fighters because range was not a major concern during combat. That has been changing in recent years, however.

“What we’ve seen happen is, with where our adversaries are heading and the improvements in their standoff capabilities, nowadays range is a much more important part for … fighters than has historically been the case,” he said.

The architecture of adaptive-cycle engines such as the XA100 can adjust the bypass ratio to favor either fuel economy, such as when a fighter is in cruise, or thrust, during combat. As such, the decision no longer has to be made between the previous two extremes; the same jet can have the best of both worlds.

Beyond the primary goal of maximizing both range and thrust, the XA100 allows for improved thermal management, which is becoming more important as more powerful aircraft systems generate more and more heat and exteriors are switched from aluminum to composite skins, which Tweedie said act like a Thermos.

According to Tweedie, the improved thermal management is accomplished through two main tactics. GE used more temperature-resistant ceramic matrix composites developed for its commercial engines and added a cool third stream that acts as a heat sink inside the engine. Most modern engines have two airstreams.

Additive technology has changed the way that GE can design engines, Tweedie said.

“Really, we’re limited only by our imagination at this point in terms of the geometries and the design configurations that we’re able to implement on parts in the engine,” he said.

GE’s XA100 adaptive-cycle engine is designed to fit the F-35A. (Lockheed Martin)

While the earlier Adaptive Versatile Engine Technology program was solely about scientific testing to prove out technology, AETP was based on applying that technology to an actual use case by choosing a platform with program requirements and proving that the adaptive engines could be developed under those restrictions and at a workable cost.

Though one of the prime potential uses for the fruits of the AETP is a sixth-gen fighter, Tweedie said the most obvious candidate is the F-35, which is the platform GE has been planning toward.

“The most direct transition for this technology would be the F-35A,” he said. “There’s talk about spinning off the technology into upgrades for 4th-gen fighters, whether that’s F-15, F-16 or F-22 platforms, and certainly it’s under considerations as we think about future platforms.”

The Air Force has spent upward of $3 billion on adaptive engine technology programs so far, with Pratt & Whitney and UTC joining GE in the AETP. However, Tweedie said that GE having been involved all throughout ADVENT and now AETP makes them feel good about where the company stands among its competition.

“We believe with all the work we’ve done on the ADVENT and early AETP, and the trajectory we’re on,” Tweedie said, “We could be ready to support the Air Force for initiation of low-risk engineering and manufacturing development programs, EMD programs, at any point in the future that they’re ready to pull the trigger.”