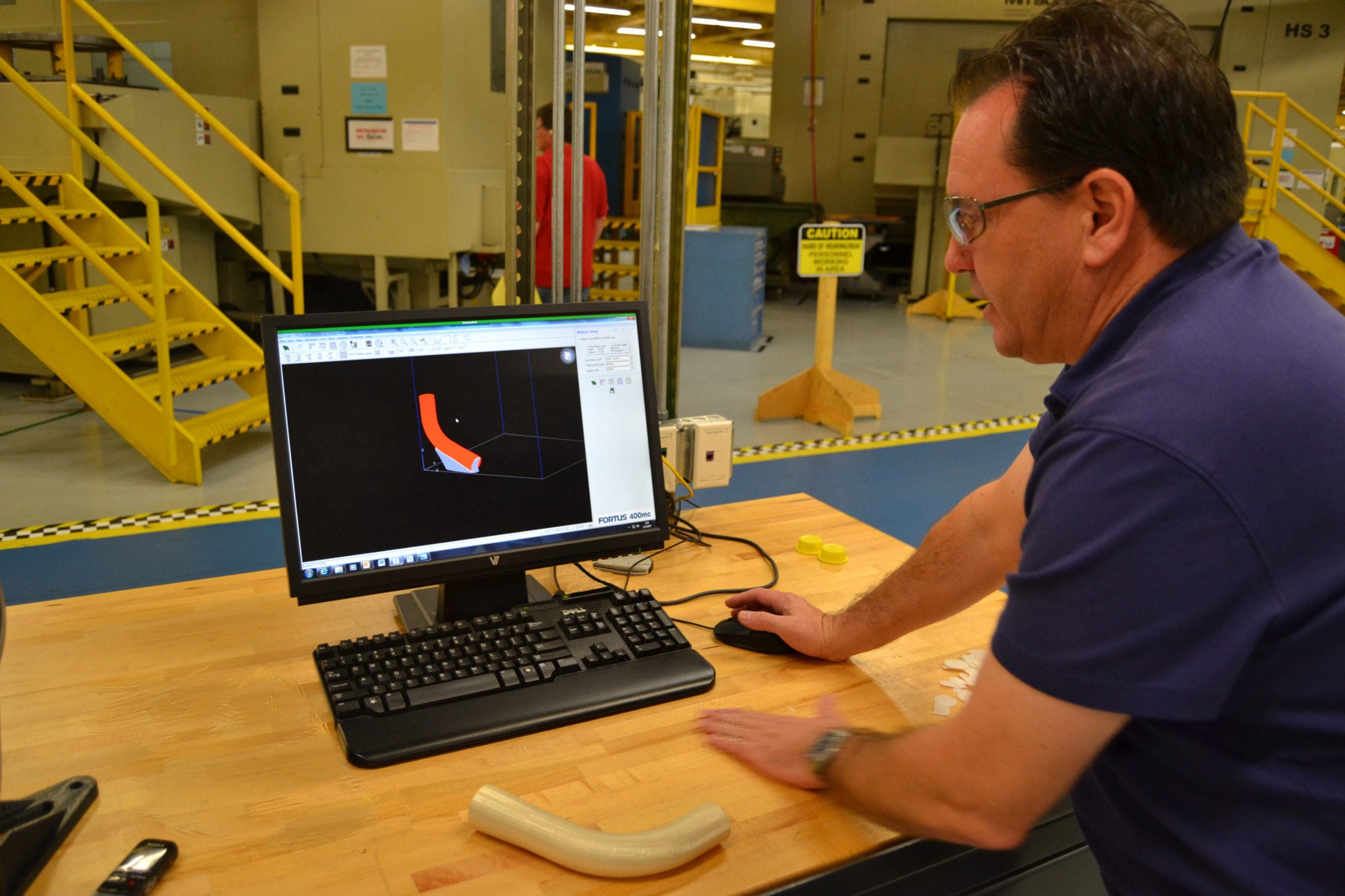

A piece of aircraft environmental duct being created with a 3D printer. Photo courtesy of the U.S. Navy

Boeing signed an agreement with Israeli company Assembrix Ltd., enabling it to use Assembrix software to manage and protect intellectual property shared with vendors during design and manufacturing.

Assembrix’s software will enable Boeing to transmit additive manufacturing design information using secure distribution methods to protect data from being intercepted, corrupted or decrypted throughout the distribution and manufacturing processes.

Boeing is focused on leveraging and accelerating additive manufacturing to transform its production system and support the company’s growth. The company currently has additive manufacturing capabilities at 20 sites worldwide and partners with suppliers across the globe to deliver 3-D-printed parts across its commercial, space and defense platforms.

“This agreement expands Boeing’s ties to Israeli industry while helping companies like Assembrix expand their business,” said David Ivry, president of Boeing Israel.

Earlier this year, Boeing invested in Morf3D and made a deal with Swiss 3D printer Oerlikon in other efforts to bolster the company’s additive manufacturing capabilities.