Global Avionics Round-Up from Aircraft Value News (AVN)

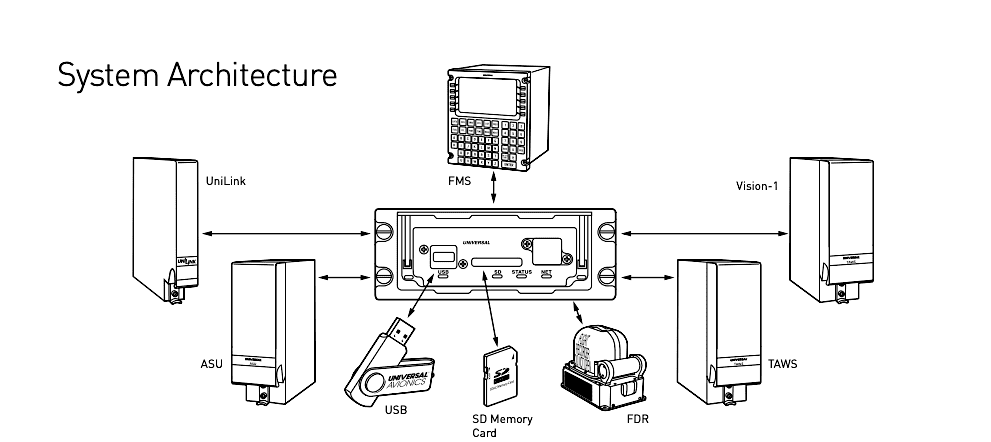

The SSDTU, pictured here in the center, is connected to all other line replaceable unit elements of the Universal Avionics flight deck system. (Universal Avionics)

The push for quieter, cleaner skies is not just about engines anymore; it’s also about the brains of the aircraft. As pressure mounts from regulators and society for net-zero aviation, and as airlines chase the dual incentives of environmental credibility and cost efficiency, electrification is surging into focus.

Some analysts argue that the rise of electric aircraft is a disruptive force poised to upend traditional aviation economics, with the potential to roil aircraft values and lease rates as new, cleaner technologies displace older, fuel-dependent models. They see electrification as the dawn of a new era that could rapidly reshape fleet planning, regional routes, and investor expectations.

Others caution that electric aircraft are overhyped in the short term, pointing to lagging battery technology, limited range, and regulatory hurdles that suggest a meaningful impact is still many years away. But even skeptics concede that the long-term trajectory is clear: electric aviation is coming, and when it arrives in full force, it will be a game changer.

Behind every electric propulsion advance is a revolution in avionics—smart systems that manage power, monitor battery health, and orchestrate seamless hybrid transitions. In this new era, avionics isn’t just supporting innovation; it is the innovation.

At the heart of this shift lies the challenge of propulsion noise and emissions. While electric motors offer the tantalizing promise of near-zero local emissions and minimal noise, their true potential is unlocked only through avionics that can precisely control energy flow, thermal conditions, and redundancy protocols.

The power densities now emerging, approaching 400 watt-hours per kilogram, may eventually allow viable regional flights, but managing that power effectively in the air demands cutting-edge onboard electronics.

Early electric trainer aircraft are already proving that avionics can deliver safe, repeatable operations with integrated battery packs. These aircraft depend not just on propulsion technology, but on avionics suites that handle power allocation, fault detection, and flight condition adaptation in real time.

Similarly, urban air mobility platforms—those multi-rotor eVTOLs being paraded at global airshows—rely on highly automated flight control systems, battery management units, and sensor fusion technologies that make safe vertical lift possible over densely populated areas.

Hybrid propulsion systems are advancing the cause further, and here too avionics plays the starring role. Consider turboprops configured for electric takeoff and climb, with combustion engines taking over at cruise.

The need for hybrid architectures…

The transition between these modes must be seamless, safe, and efficient, something only possible with sophisticated hybrid control architectures that govern power draw, monitor environmental variables, and balance energy sources based on mission profile.

Even legacy aircraft are being drawn into the electrification movement. Retrofit programs are beginning to swap conventional components with electric subsystems that promise reduced greenhouse gas emissions, improved efficiency, and lower maintenance demands due to fewer moving parts. But the real transformation isn’t mechanical; it’s digital.

Pilots and engineers from American Airlines and L3Harris in 2019 completed flight tests evaluating the use of SafeRoute+ ADS-B In retrofit technology. Photo: L3Harris

These retrofits require new avionics interfaces, intelligent power distribution units, and systems integration that allows pilots and flight control systems to manage novel failure modes.

This “more-electric” aircraft architecture isn’t entirely new. The Boeing 787 was an early trailblazer, replacing hydraulic and pneumatic systems with electrically driven ones, such as the environmental control systems. But the evolution since then has been dramatic. Avionics developers are now exploring full aircraft microgrids. i.e. smart power distribution networks that route electricity based on in-flight needs, mission type, and even predictive battery diagnostics.

Modern aircraft avionics are also evolving to accommodate new realities in power electronics. Rapid switching, real-time load balancing, and intelligent thermal management are now table stakes. Developers are investing heavily in wide-bandgap semiconductors (like silicon carbide and gallium nitride) that enable these capabilities, creating avionics systems that are lighter, faster, and far more efficient than their predecessors.

But the challenges remain significant. The dream of electric aviation still wrestles with battery chemistry tradeoffs: the more energy-dense a cell, the more difficult it becomes to ensure thermal stability, long lifespan, and safety. That places enormous pressure on avionics to serve as both watchdog and traffic cop, preventing thermal runaway, managing redundant failovers, and enabling pilots to diagnose and respond to electrical anomalies mid-flight.Certification is another hurdle where avionics will play a central role. Electric aircraft don’t conform to legacy categories, and their failure modes, such as electrical arcs, battery faults, and inverter breakdowns, require new standards.

Regulators are slowly adapting, and some jurisdictions are exploring regulatory “sandboxes” to allow real-world flight testing under controlled conditions. These testbeds are critically reliant on avionics that record, log, and analyze thousands of data points per second for later review and standards development.

Charging infrastructure, too, is being shaped by avionics needs. Aircraft will need to communicate with ground systems to validate charge levels, manage battery swaps, and verify power flow integrity before takeoff. This level of interconnectivity calls for new protocols, secure data links, and integration with airport systems, another domain where avionics holds the key.

Despite the hurdles, the momentum is unstoppable. Every major aircraft OEM is exploring electric or hybrid designs, and new avionics systems are emerging to support these configurations. eVTOL firms are rolling out integrated flight management and energy systems purpose-built for short-haul vertical lift, while regional aircraft prototypes feature cockpit displays and control logic optimized for electric performance metrics, not just traditional fuel burn.

Governments are helping fund this avionics-heavy innovation through grants, carbon-offset-linked incentives, and pilot programs. Airlines, too, are investing, by joining sustainability consortia and embedding electric flight goals into their “green” targets. Many of these efforts hinge not just on propulsion breakthroughs, but on avionics platforms that ensure these systems function reliably in real-world conditions.

In the near term, expect hybrid aircraft to lead the way, reducing fuel burn and emissions on short-haul routes. Within a decade, cityscapes may host quiet electric air taxis guided by autonomous avionics systems capable of adaptive navigation and instant energy reallocation. Eventually, long-haul flights may follow, but only if avionics technology continues to mature in step with propulsion and materials science.

The aviation revolution won’t be signaled by a new kind of wing or engine alone. It will be defined by what pilots see on their screens, how flight computers make decisions, and how energy flows across a smart airframe. The quiet hum of an electric aircraft in the sky may indeed be the most profound sound in aviation’s future, and behind that sound will be an orchestra of avionics doing the heavy lifting.

This article originally appeared in our partner publication, Aircraft Value News.

John Persinos is the editor-in-chief of Aircraft Value News.