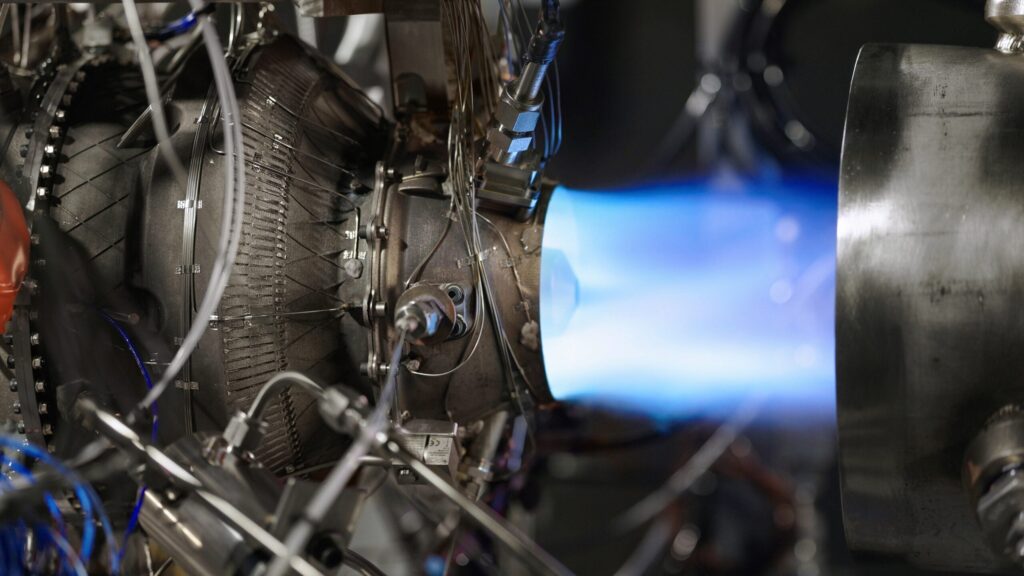

First fire of Beehive Industries’ Frenzy engine. (Photo: Beehive.)

Beehive Industries, a propulsion startup firm, said on Sept. 22 it’s ramping up testing of its Frenzy line of additively-manufactured engines, with plans to conduct altitude testing of a 200-pound version in October before moving to flight testing early next year.

Gordie Follin, Beehive’s chief product officer, told sister publication Defense Daily the company anticipates the Air Force would next move the Frenzy engine into production following successful flight testing and that the system could power UAVs used for Air Launched Effects and counter-drone purposes.

“I think what Frenzy allows you to do is to be able to produce higher quantities of these types of systems. They also have better performance, which means it can extend the range, so now you can engage your adversaries from farther away. And they’re also lower cost, so that allows you to be able to purchase them in higher quantities than what you’ve been able to do in the past,” Follin said.

Beehive is working on the low-cost Frenzy engine under a $12.4 million agreement with the University of Dayton Research Institute (UDRI) sponsored by the Air Force, noting it first introduced the capability last December.

“The Frenzy engines, designed for immediate usability after long-term storage of over 10 years, are poised to revolutionize UAV operations by offering class-leading efficiency at a fraction of the cost of traditionally manufactured engines,” Beehive said in a statement.

Since initiating work on Frenzy, Beehive said it has “accelerated the development process,” to include achieving a first engine to test milestone within five months and then testing a new engine every six weeks.

“This unprecedented speed highlights Beehive’s ability to compress traditional development timelines from years to months, a feat made possible by its innovative design and production techniques,” Beehive said.

The 200-pound version of the Frenzy engine has completed acceptance testing and will be shipped soon to the Air Force Research Laboratory’s facility in Ohio for the upcoming altitude testing.

For next year’s planned flight testing, Follin said he could not disclose what air vehicle will be used for that demonstration.

The four different Frenzy engines tested to date range from five to eight inches in diameter and 100 to 300 pounds, with each of the systems having completed performance and operability validation, durability validation and environmental stress testing, according to Beehive.

“Each engine individually surpassed better-than-target power, better-than-target Specific Fuel Consumption and more than a full mission of operational durability; collectively, they accumulated more than 20 hours of runtime,” Beehive said. “Far from being mere demonstrations, these engines have already met or exceeded all product requirements.”

Follin noted that part of its contract with UDRI is intended to demonstrate that the Beehive design could be manufactured by a third party.

“So UDRI will be owning that part of the scope of work as Beehive is going to deliver to them the engine design, and they’re going to manufacture it to prove that it can be made independent of [the] Beehive manufacture process,” Follin told Defense Daily.

A version of this story originally appeared in affiliate publication Defense Daily.