|

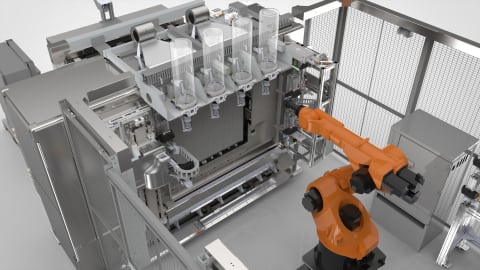

| The Stratasys Infinite-Build 3D Demonstrator. Photo: Stratsys |

[Avionics Today 08-24-2016] Stratasys, a 3D printing and additive manufacturing company, is preparing to reveal technology demonstrators that aim to address manufacturers’ needs to rapidly produce aerospace parts, such as the aircraft interior panel.

The first demonstrator, the Stratasys Infinite-Build 3D Demonstrator is designed to address the requirements of aerospace and other industries for large lightweight, thermoplastic parts with repeatable mechanical properties. The system turns the traditional 3D printer concept on its side to realize an “infinite-build” approach, which prints on a vertical plane for practically unlimited part size in the build direction.

Boeing played an influential role in defining the requirements and specifications for the demonstrator, and is currently using an Infinite-Build 3D Demonstrator to explore the production of low volume, lightweight parts.

“We are always looking for ways to reduce the cost and weight of aircraft structures, or reduce the time it takes to prototype and test new tools and products so we can provide them to customers in a more affordable and rapid manner. The Stratasys Infinite-Build 3D Demonstrator enables products to be made at a much larger and potentially unlimited length, offering us a breakthrough tool to add to our robust additive manufacturing processes,” said Darryl Davis, president of Boeing Phantom Works.

The second demonstrator, the robotic Composite 3D Demonstrator aims to integrate core additive manufacturing technologies with motion control hardware and design-to-3D printing software capabilities provided by Siemens. The demonstrator is designed to revolutionize the 3D printing of composite parts.